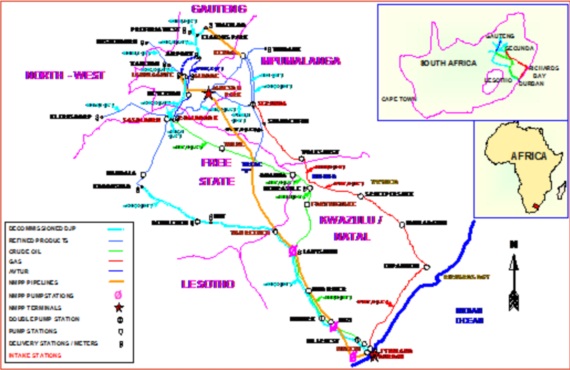

The infrastructure for the pipeline started in the 1960s when it was determined that the railway lines from Durban and Mozambique were deemed inadequate to meet inland markets in Gauteng. From this beginning a 12 inch pipeline was commissioned from Durban to Gauteng (formerly Witwatersrand). The historic development is presented below:

- 1960 Construction of a 12 inch pipeline for refined petroleum products

- 1969 An 18-inch crude oil from Durban to inland refinery (NATREF) at Coalbrook in the Free State.

- 1973 2nd 16 inch pipeline for refined products. This was under-utilized due to the synthetic fuel line (coal to oil) construction in Secunda.

-

1995 Petroleum line reconfigured to transport methane rich gas (Secunda to Durban via Empangeni)

- Transnet Pipelines is responsible for 3,300km

-

590km is owned by Caltex (moving crude oil to their refinery at Calref).

-

Out of the 21 plus billion liters conveyed annually, Pipelines moves 16-17 billion while Caltex moves ~ 5 billion liters.

The length of the network is as follows:

The infrastructural profile of the pipeline and respective design capacity is presented below. These are categorized by key commodities handled; namely, crude oil, refined fuels, aviation turbine fuel line and methane-rich gas.

-

Crude Oil Line: 580 km

- Design cap = 6.8 bnl/a

- Current cap = 5.2 bnl/a

- Refined Fuels Line: 725 km plus +/- 1,000 km network

- Design cap = 3.5 bnl/a

- Current cap = 4.3 bnl/a

- Aviation Turbine Fuel Line:94 km

- Design cap = 1.2 bnl/a

- Current cap = 1.1 bnl/a

- Methane-Rich Gas Line:+/- 570 km

- Design cap = 23 m GJ/pa

- Current cap = 17 m GJ/pa

The revised implementation plan for the NMPP necessitates the use of both the NMPP and the Durban to Johannesburg Pipeline (DJP) for the 2012 and 2013 years to meet market demands.

Staff up to 700 employees by 2013 to ensure that the transition into the new business environment with NMPP is successful.

Continued interactions with regulatory Authorities in this dynamic environment to facilitate regulatory reform and to ensure alignment and cooperation amongst all stakeholders. It will be imperative to ensure that the tariff methodology is stabilized so that funding of strategic projects can continue with relative certainty and stability.

The pipeline network traverses the following provinces: KwaZulu natal, Free State, Gauteng, North West and Mpumalanga.. Intake stations are located in Durban (at the refineries) with the crude at Coalbrook (NATREF- Natal Refinery); and the Sasol 2 and 3 synfuel plants located at Secunda.

The network also comprises of a tank farm at Tarlton with capacity of 30 million liters. This facility is used for storage and distribution of liquid fuels into Botswana. The gas pipeline originates from Secunda to Durban via Empangeni with take-off points at Newcastle and Richards Bay and all along the route.

The Pipeline Network - 2010

The four major pipelines are constructed in terms of American Society Mechanical Engineers (ASME) B31.4 (liquid petroleum products) and B31.8 (gas) standards. The system operates. at maximum allowable pressures of 100 bar in the case of petroleum products and 59 bar for gaswith Pipeline pressures continually monitored from a central control centre from which product planning, scheduling and co-ordination is also controlled.

Monitoring of the system is under automatic tele-control utilising state-of-the-art control systems. Real-time modeling enables the exact position to be determined of any product slug at any time. Metering is undertaken in accordance with American Petroleum Industry (API) standards and Custody Transfer Agreements, to an accuracy of 0, 1%.

Further monitoring of pressure within the pipeline network is 24 hours a day, 365 days a year at the control center in Durban (Pipelines Head Office). Maintenance of the system is by internal inspection tools known as Intelligent Pigs. These use the magnetic stray flux principle to determine and record possible areas of metal loss from corrosion or any other anomalies. The O &M plan is under review and on-going monitoring is conducted by a Steering Committee.

The plan consists of:

- Phase 1 NMMP commission

- De-commissioning of a section of refined product line (Durban-Fynnland and Kroonstad).

Other prospective Pipelines besides the NMMP:

- Mozambique - Gauteng Pipeline (Petroline planned to construct and operate has a license from NERSA)

- Waterberg Synthetic Fuels Pipeline - this is linked to results by Sasol on investigations of coal reserves in Waterberg region.

The longer-term view consists of the following

- A direct link between the proposed PetroSA refinery in the Coega Industrial Development Zone and Sasolburg.

- A new refined products pipeline from the port of Maputo to Kendal (Gauteng) and the inland network

Copyright © 2010 Mpumalanga Province Freight Transport Data Bank [ - ]

All rights reserved.

This website conforms to W3C Standard [ - ]