Primary commodities and associated volumes handled are as follows:

- Refined and synthetics conveyed by a 440 m3 hour/12" pipeline

- Commodities: petrol, diesel and aviation turbine fuel

- Crude Oil conveyed by pipelines with varying diameters such as

- Durban (Fynnland) - Ingogo: 16"

- Ingogo - Sasolburg (Coalbrook): 18"

- Vrede - secunda: 18"

- Secunda - Kendal: 20"

- Avtur conveyed from a 6" aviation pipeline from NATREF Coalbrook via Meyerton to OR Tambo.

- Gas conveyed via plant at secunda to Durban via Standerton, Volksrust, Ingogo, Scheepersnek, Mahlabathini and Empangeni

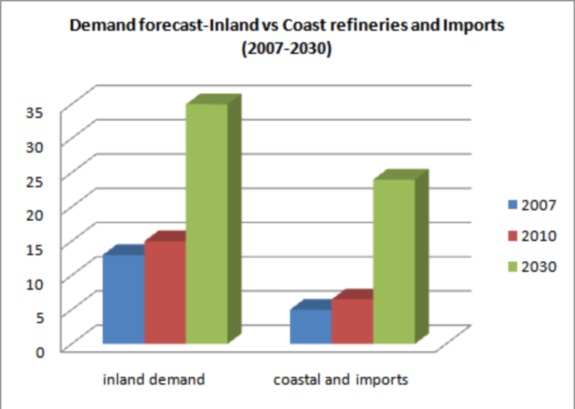

Inland demand forecast and supply from coastal refineries & direct imports are:

Demand Forecast -Inland vs Coast Refineries and Imports

Primary Commodity Volumes (Actual vs Target) 2009-2011

Observations:

- Refined and synthetics increased by 6.6% compared to previous year.

- Crude oils decreased by 1.2% due compared to previous year due to NATREF "Production problems."

- Avtur decreased by 8.9% due to Bridging plan which will transfer coastal Avtur volumes to Transnet Freight rail.

- Gas was definitely lower attributed to sluggish economy.

Demand Forecast for key commodities (2008-2022)

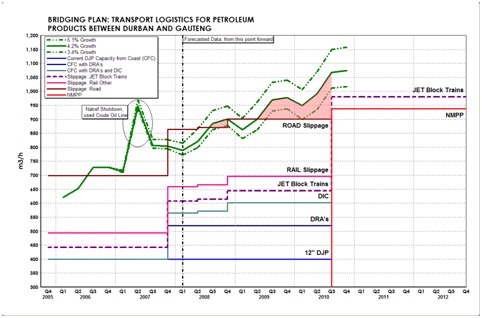

In response to numerous operational challenges due to lack of demand capacity, the Bridging Plan first developed in 2007 is presented below as contained in the Transnet National Infrastructure Plan - 2008.

The majority of the fuel in South Africa is consumed in the "inland" region of the country; the magisterial districts that constitute this area are represented by the dark blue shading in the following figure. The supply sources for this region are the two inland refineries (NATREF and Secunda), the two coastal refineries (ENREF and SAPREF), imports via Durban and small volumes of import via Maputo.

Currently the demand in the inland region exceeds the supply of the two inland refineries and this amongst other commercial and contractual arrangements has necessitated the transport of liquid fuel to the inland from the coast; road, rail and pipeline are utilised to fulfill this need. The inherent safety, cost-effectiveness, reliability, ability to convey large volumes and environmental friendliness of the pipeline transport mode makes it the preferred mode of delivery. Current inland demand exceeds the available pipeline capacity and volumes transported by other modes (primarily road) have increased accordingly, but considerations of road safety, cost to the national economy and accelerated wear and tear of the road infrastructure make this situation unsustainable in the long-term. Additional pipeline capacity will be commissioned in third-quarter 2010, in the form of the New Multi-Products Pipeline (NMPP), but continuity of supply has had to be alternatively addressed in the interim. Transnet Pipelines has identified a number of interim initiatives intended to improve delivery of liquid fuels to the Gauteng area in advance of the commissioning during third-quarter 2010 of the first phase of a new multi-product pipeline. Collectively known as the Bridging Plan, the concept of which is to create marginal additional capacity just ahead of growing demand, these initiatives are described in greater detail below.

Operational Changes on Refined Products Pipeline Network

A number of actions have been implemented to improve the operational efficiency of the existing pipeline network. In combination the following initiatives have increased throughput from an average of 63 to 68 million litres per week:

- Industry-co-ordinated planning.

- Achievement of economies of scale by means of increased batch sizes.

- Use-based allocation of pipeline capacity.

- Implementation of penalties/service fees in respect of delays.

- Optimisation of planned maintenance downtime.

- Investment in de-bottlenecking facilities at Jameson Park and at the Coalbrook/Sasolburg complex.

Drag-Reducing Agents in Durban - Johannesburg Pipeline

Drag-Reducing Agents (DRAs) are long-chain hydrocarbon polymers of very high molecular weight which reduce stream friction, and thereby improve flow-rates, by aligning themselves with flow direction. A spin-off benefit is a reduction in power consumption for the same volume of liquid conveyed. It is, however, necessary to re-inject DRAs after each pumping stage as they are mechanically sheared by pipeline pumps.

Extensive testing with industry during 2007 proved that DRAs did not compromise product quality and a test-run between Durban and Ladysmith showed a 33% improvement in flow-rate without any detrimental effect on pipeline equipment or fuel specification. Starting in November 2007, the injection of chemical drag-reducing agents (DRAs) into the DJP has improved pipeline flow-rates thereby enhancing average delivery volumes from 70 to 82 megalitres per week without having to increase pumping capacity. Since DRAs cannot be applied to aviation turbine fuel, the shedding of this fuel to rail (as described below) will enable the volume to be further increased to 85 megalitres per week.

Diesel in Crude-oil Pipeline (Phase 1)

The "Clean Fuels" legislation of 2005 reduced the output of the NATREF (Coalbrook) refinery, requiring less crude-oil to be conveyed from the coast. The design capacity of the crude-oil pipeline is 840m3/h but NATREF's current processing requirement has resulted in the pipeline running at only approximately 720 - 730 m3/hr (about 85% of design capacity). The opportunity thus arose to utilise the approximately 100m3/h of spare "headroom" capacity to pump additional quantities of diesel (hence the use of the term "Diesel in Crude", abbreviated to the acronym DIC) without affecting in any way the refinery's operational flexibility.

Mixing of adjacent product batches (known as "slugs") is obtained by devices known as "pigs", which are introduced into the pipeline between the slugs. At the destination the interface zone is generally separated from the batches and separated out.

Similar devices are used to clean the inside walls of the pipe, to X-ray it and to enable it to be examined optically (by means of a remote camera). In terms of the diesel-in-crude initiative a slug of diesel is transported between slugs of crude oil. The diesel slug does not require re-refining on receipt at NATREF, but the crude-diesel interface zone does need to be managed, and copper and silver anti-corrosion treatments need to be applied to the remainder of the slug prior to it being re-certificated for distribution.

Although the opportunity will only exist until NATREF invests in equipment to increase its refining capacity, the limiting factor will be NATREF's ability to process the crude/diesel interface zone (the zone where crude oil and diesel mix), which has limited current uptake to some 30 megalitres per month in a single slug. Over half a billion litres of additional product has been delivered to the market as a result of this initiative.

The literature below contains a direct discussion from Transnet and how the collaboration between pipeline and rail will come conducted. It is worth reviewing the logic and likely challenges and opportunities this cooperation will provide the country (Bridging Plan) as the NMMP is under construction and initial operation.

In some instances deliveries of liquid fuels have been negatively influenced by systemic constraints. A good example of this is the case of aviation turbine fuel (Avtur), largely delivered to OR Tambo International Airport (ORTIA) by pipeline. The very stringent purity standards that are applied to the commodity have obliged the taking of special precautions for its conveyance, the effect of which has been to reduce overall deliveries into the Gauteng area. Conversely, if Avtur was removed from the pipeline system then its capacity would increase.

The concept of this collaborative Transnet Freight Rail/Transnet Pipelines initiative is thus to increase delivery volumes during the period of the Bridging Plan by re-defining the destinations that will be served by pipeline and those that will be served by rail, such as the delivery of aviation turbine fuel to OR Tambo International Airport (ORTIA), and those that will be supplied by pipeline, such as Waltloo.

Modalisation of deliveries does not imply, however, that the preferred mode of delivery will be the only mode. In the case of ORTIA, for example, although rail will be the preferred mode of delivery, in order to ensure security of supply pipeline delivery will be retained as a fall-back option.

The initiative has also resulted in the introduction of dedicated liquid fuels block-trains, the so-called Energy Express, to selected destinations and will add additional capacity of approximately 1.5 billion litres per year. The green line of the accompanying graph represents the inland demand that has to be met by ex-coast conveyance of refined product; prior to the late-2008 reduction in demand (by some 10% according to oil industry sources) quarters 3 of 2008, 2009 and 2010 would have needed additional focus.

Bridging Plan 1

Bridging Plan 2

Bridging Plan 3

Copyright © 2010 Mpumalanga Province Freight Transport Data Bank [ - ]

All rights reserved.

This website conforms to W3C Standard [ - ]